Master Modular Wall Installation Techniques in Californiato ensure faster build times, flexible configurations, and code-compliant containment solutions tailored to the state’s strict standards. At 5DCCS (Construction Containment Services), we help contractors and facility managers across California streamline modular wall projects through expert planning and field-tested installation techniques. Whether you are building clean environments, isolating job sites, or constructing long-term barrier systems, this guide delivers the essential steps and insights to complete your installation with confidence.

Understanding Modular Wall Systems and Their Benefits

Modular wall systems are prefabricated wall panels designed to be quickly assembled, disassembled, or reconfigured with minimal disruption. These systems are widely used in construction containment, cleanrooms, warehouses, healthcare facilities, and industrial plants where flexibility, hygiene, and speed matter most.

At 5DCCS, we work with a variety of modular wall types to meet the diverse needs of California job sites. Common applications include isolating construction zones within active facilities, containing dust or airborne particles, and creating clean, controlled environments. These systems often use interlocking panels, lightweight aluminum framing, and customizable finishes, allowing for easy installation without major structural changes.

Benefits of modular wall systems include:

- Speed of Installation:Prefabricated components allow faster deployment than traditional framing and drywall.

- Reusability and Flexibility:Panels can be reconfigured for future phases or moved to new locations.

- Clean Aesthetic:Ideal for customer-facing or regulated environments where cleanliness and appearance are important.

- Minimal Downtime:Projects can continue with less interruption to existing operations.

- Cost Control:Faster builds and reusable materials reduce long-term expenses.

California projects in particular benefit from modular walls due to evolving code requirements and frequent retrofit needs. These systems offer a practical solution that aligns with sustainability goals, labor efficiency, and space optimization.

Pre-Installation Planning for California Projects

Effective planning is the backbone of a successful modular wall installation, especially in California where regulatory, seismic, and environmental factors must be carefully addressed. At 5DCCS, we prioritize thorough pre-installation planning to prevent delays, cost overruns, and compliance issues.

Key steps in pre-installation planning include:

- Site Survey and Layout Design:Begin with a detailed assessment of the site, including measurements, floor conditions, and obstruction mapping. Accurate layout drawings ensure proper alignment and material estimation.

- Measuring and Tolerances:California job sites often deal with irregular dimensions or sloped surfaces. Allowance for tolerances and leveling is critical to avoid panel gaps or misalignment during installation.

- Timeline and Logistics Planning:Modular wall installations are faster than traditional methods, but coordinating delivery, staging, and labor remains essential. We recommend building lead time into the schedule to accommodate permit approvals and material transit.

- Coordination with Other Trades:Modular walls are often installed in active environments. Communicating clearly with electrical, HVAC, and plumbing teams helps prevent interference with panel paths or support systems.

- Compliance Preparation:Before installation, ensure all documents, product data, and engineering drawings are ready for submission to local authorities. California’s permitting process can vary by jurisdiction, so having your paperwork in order helps avoid costly delays.

By starting with a comprehensive plan, contractors and project managers set the stage for a smooth, efficient installation that meets California’s high construction standards.

Key Materials and Components for Modular Wall Installation

Understanding the right materials and components is essential for a secure, code-compliant modular wall installation. Most modular wall systems come equipped with essential parts by design. However, every job site presents unique challenges. That’s where 5DCCSplays a critical role. We provide and integrate the missing components required to ensure every installation is completed efficiently and securely across California.

Core materials and components include:

- Wall Panels:These prefabricated panels form the backbone of modular systems. Available in powder-coated steel, vinyl-faced gypsum, or composite materials, they are engineered for quick assembly and clean finishes. 5DCCS ensures panels are matched to the required performance and fire-rating standards for each project.

- Framing and Posts:Structural framing, typically aluminum or galvanized steel, supports the overall system. Posts connect corners, terminations, and transitions. If a wall system lacks these supports, 5DCCS supplies and installs the correct framing for long-term stability.

- Connection Hardware:Clips, gaskets, and fasteners hold panels in place and maintain alignment. When hardware is missing, outdated, or incompatible, 5DCCS provides upgraded solutions that meet California’s seismic and environmental conditions.

- Finishes and Accessories:From cleanroom-grade finishes to high-durability coatings, surface treatments should match the function of the space. 5DCCS also supplies doors, pass-throughs, vision panels, and other integrated features as needed.

- Sealants and Anchoring Systems:For spaces requiring airtight containment or heavy-duty durability, 5DCCS provides specialty sealants and floor or wall anchoring systems. Our components meet California code requirements and field-tested performance benchmarks.

By closing the gaps in prefabricated systems, 5DCCS ensures every modular wall installation is complete, secure, and built to last.

Step-by-Step Installation Process

Installing modular wall systems efficiently requires a clear sequence, precise coordination, and the ability to adapt to on-site conditions. At 5DCCS, our field teams follow a proven step-by-step process that ensures safety, speed, and long-term performance, especially on complex California job sites.

Here’s how we approach each installation:

- Delivery and On-Site Staging:Materials are delivered to the site and staged in an order that aligns with the layout plan. This reduces handling time and ensures installers have quick access to the components they need.

- Anchoring and Leveling:The first critical step is to anchor the base track and verify level across the installation path. California sites often present sloped or uneven slabs, which we correct using shims, leveling systems, and precision tools.

- Panel Placement and Connection:Panels are installed sequentially, connecting to framing posts or tracks using secure hardware. As each panel is placed, our team checks for alignment and spacing to maintain a clean, uniform finish.

- Integration of Doors and Accessories:Once the primary wall run is established, 5DCCS installs doors, windows, and other integrated accessories. Openings are verified against spec drawings, and all inserts are sealed and secured.

- Sealing and Finishing Touches:Depending on containment or cleanroom requirements, sealants are applied at floor, ceiling, and panel joints. Finishing trim, caps, and closure panels are added for both appearance and function.

- Quality Inspection and Adjustments:A final inspection ensures everything meets structural, aesthetic, and compliance standards. Any necessary adjustments are made before the project is turned over.

Each step is planned and executed with care to minimize disruption, meet deadlines, and deliver lasting performance. When your project depends on reliability and compliance, 5DCCS brings the discipline and expertise to install with confidence.

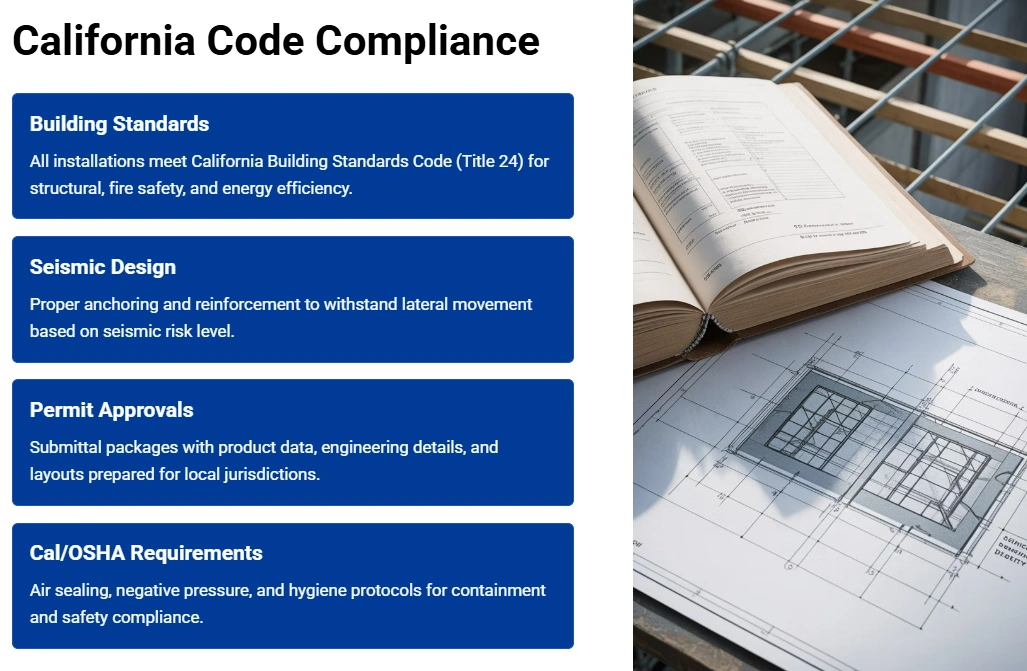

California-Specific Considerations: Codes, Seismic and Permits

Modular wall installations in California must meet some of the most stringent building regulations in the country. From seismic design to environmental compliance, planning around local and state requirements is essential for project approval and long-term performance. At 5DCCS, we specialize in navigating these complexities to ensure every modular wall system is built to code.

Key California-specific factors include:

- Building Code Compliance:All installations must meet the California Building Standards Code (Title 24), which outlines structural, fire safety, and energy efficiency criteria. 5DCCS ensures that all modular components are selected and installed to meet or exceed these standards.

- Seismic Design Requirements:California’s seismic zones require wall systems to be properly anchored and reinforced to withstand lateral movement. Our team evaluates anchoring methods, panel bracing, and structural framing based on the seismic risk level of your project site.

- Permit Approvals:Local permitting processes vary by city and county. 5DCCS helps clients prepare submittal packages, including product data sheets, engineering details, and layout drawings. Our familiarity with jurisdictions throughout the state speeds up approvals and reduces delays.

- Environmental and Containment Regulations:For jobs involving dust, hazardous materials, or clean environments, additional containment standards may apply. We install modular systems that support air sealing, negative pressure setups, and hygiene protocols to satisfy California Occupational Safety and Health Administration (Cal/OSHA) requirements.

- Energy and Accessibility Standards:Modular installations must often incorporate energy-efficient lighting, insulation, or accessibility features, depending on their use and location. 5DCCS integrates these needs into the wall system design whenever required.

By working with a partner that understands California’s regulatory landscape, your project avoids unnecessary setbacks and remains fully compliant from day one.

Common Installation Challenges and How to Solve Them

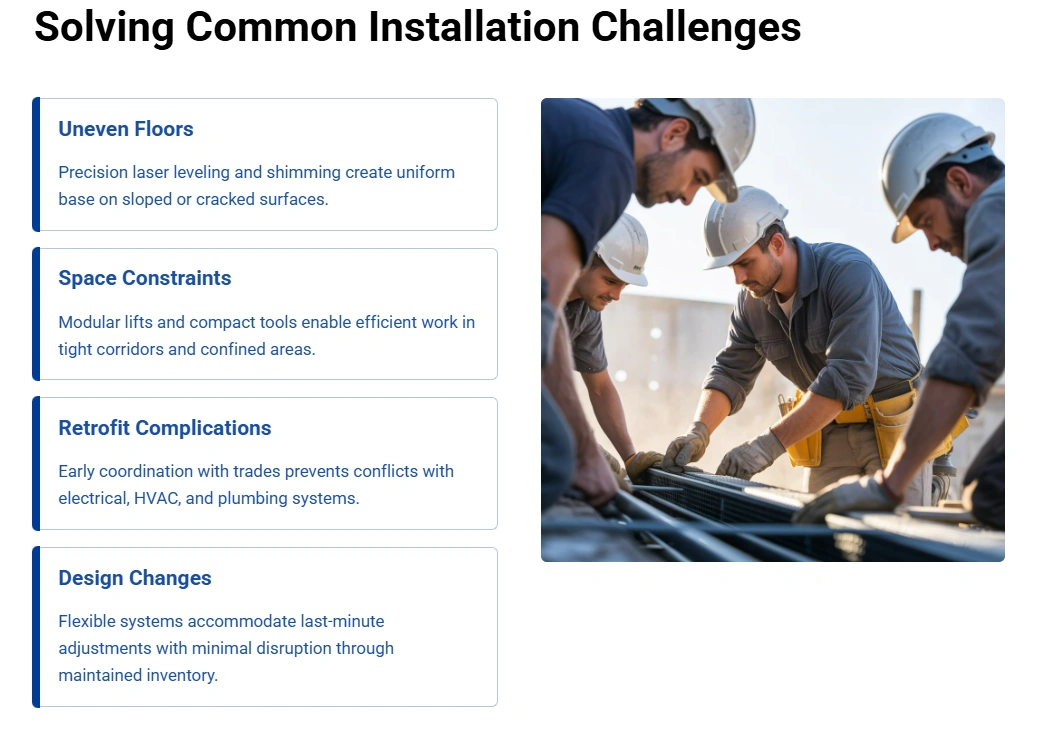

Even with prefabricated systems, modular wall installations can face unexpected challenges, especially in dynamic California environments. At 5DCCS, we anticipate these issues and implement proven solutions to keep projects on track.

Here are some of the most common challenges and how we solve them:

- Uneven or Irregular Floor Surfaces:Many California job sites have sloped, cracked, or unlevel flooring. To ensure stable walls, 5DCCS uses precision laser leveling and shimming techniques to create a uniform base before installation begins.

- Space Constraints and Tight Access:In retrofit projects or operational facilities, tight corridors or overhead obstructions can complicate staging and panel placement. Our crews use modular lifts, compact tools, and pre-staged sequences to work efficiently in confined areas.

- Retrofit Complications:Adding modular walls to existing structures often reveals conflicts with electrical, HVAC, or plumbing systems. 5DCCS coordinates with other trades early in the planning phase to adjust layouts or select compatible panel cutouts and accessories.

- Weather and Climate Exposure:Although many installations occur indoors, outdoor or semi-conditioned environments introduce temperature and humidity variables. We select materials with appropriate thermal expansion tolerances and install with moisture control strategies in mind.

- Last-Minute Design Changes:Projects can evolve during construction, requiring layout adjustments or added features. Because modular systems are inherently flexible, 5DCCS can accommodate changes with minimal disruption by maintaining inventory and fabrication access.

By proactively addressing these challenges, we help clients avoid costly rework and ensure their modular wall systems perform as expected from day one.

Maintenance and Long-Term Performance of Modular Walls

One of the biggest advantages of modular wall systems is their long-term value. With the right care and occasional updates, they can serve your facility for years without the need for major renovation. At 5DCCS, we help clients protect their investment through straightforward maintenance and scalable reconfiguration support.

To ensure maximum performance over time, consider the following:

- Regular Inspection Protocols:Visual inspections should be conducted periodically to check for panel separation, loose hardware, or sealant wear. Early detection allows for quick fixes and extends the life of the system.

- Cleaning and Surface Protection:Most modular wall panels are designed with durable, cleanable surfaces. Use non-abrasive cleaners and soft cloths to maintain a clean appearance without damaging coatings. For cleanrooms or healthcare settings, approved disinfectants may be required.

- Reconfiguration and Expansion:Modular systems are designed to evolve with your needs. If your space layout changes, 5DCCS can disassemble and reassemble the wall system to match your new configuration without significant downtime or material waste.

- Hardware Replacement and Upgrades:Over time, door closers, locks, or gaskets may need replacement. We stock compatible hardware and provide service to keep your system functioning safely and smoothly.

- Warranty and Service Support:5DCCS stands behind our work. We provide clear warranty information and ongoing support to assist with troubleshooting, parts replacement, or system modifications.

With routine care and expert support, modular walls offer a long-term, adaptable solution that continues to meet your operational goals year after year.

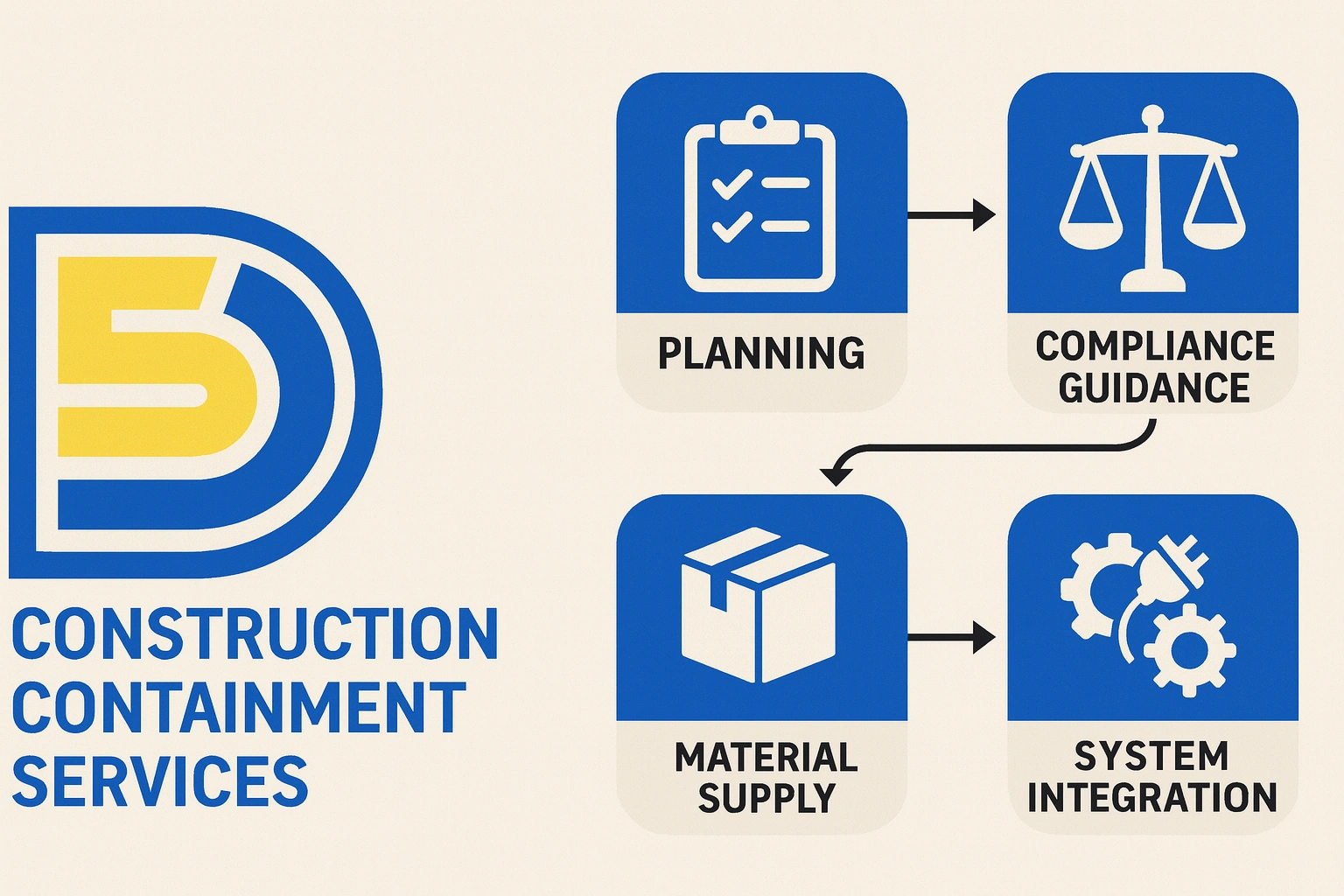

Why Choose 5DCCS for Your Modular Wall Installations

At 5DCCS (Construction Containment Services), we are fully equipped to support modular wall installations across California with expert planning, field-tested components, and service-focused solutions. While we have not yet performed installations directly, our deep knowledge of modular systems, California construction codes, and containment strategies positions us as a reliable partner for contractors, facility managers, and project teams preparing to deploy these systems.

Here’s how 5DCCS supports successful modular wall installations:

- Expertise with Leading Modular Systems: We work with top-tier modular wall manufacturers and understand how to adapt their products to real-world conditions. Whether you’re using a standard kit or a custom configuration, our crews are trained to install it correctly the first time.

- Component Supply and System Integration:We provide the critical components that modular systems may lack, including anchoring hardware, framing posts, sealants, and accessories tailored to California job site needs.

- Code and Seismic Guidance:Our team helps ensure your modular wall setup complies with California Building Code and seismic requirements. We assist in selecting the right materials and preparing documentation for local approvals.

- Planning and Field Readiness Support:From layout planning to site prep recommendations, 5DCCS works with your team to prepare for efficient, code-compliant installation with minimal disruption.

- Product Knowledge and Adaptability:We understand the strengths and limitations of different modular wall systems. Our solutions help bridge performance gaps, improve containment, and extend usability.

- Scalable Support Model:Whether you are planning a small retrofit or a large-scale installation, we scale our services to meet your timeline, budget, and site conditions.

When your project calls for modular wall systems in California, 5DCCS is ready to support your successwith the right tools, materials, and technical insight to help you move forward with confidence.