Best Modular Temporary Wall Maintenance Tips in Californiaaren’t just general advice. They’re essential guidelines for maintaining the performance and durability of modular wall systems across the San Francisco Bay Area. At Construction Containment Services (5DCCS), we’ve seen how proper maintenance can extend the life of modular temporary walls used in healthcare facilities, construction sites, data centers, and cleanrooms.

With the Bay Area’s unique blend of coastal moisture, fluctuating microclimates, and dense urban activity, facilities need a localized approach to care. Whether you’re managing a renovation in San Jose or maintaining cleanroom integrity in Oakland, regular upkeep protects safety, prevents damage, and preserves long-term value.

In this guide, we’ll share practical tips tailored to California’s environment that help keep your modular containment walls clean, compliant, and durable.

Why Maintenance Matters for Modular Temporary Walls

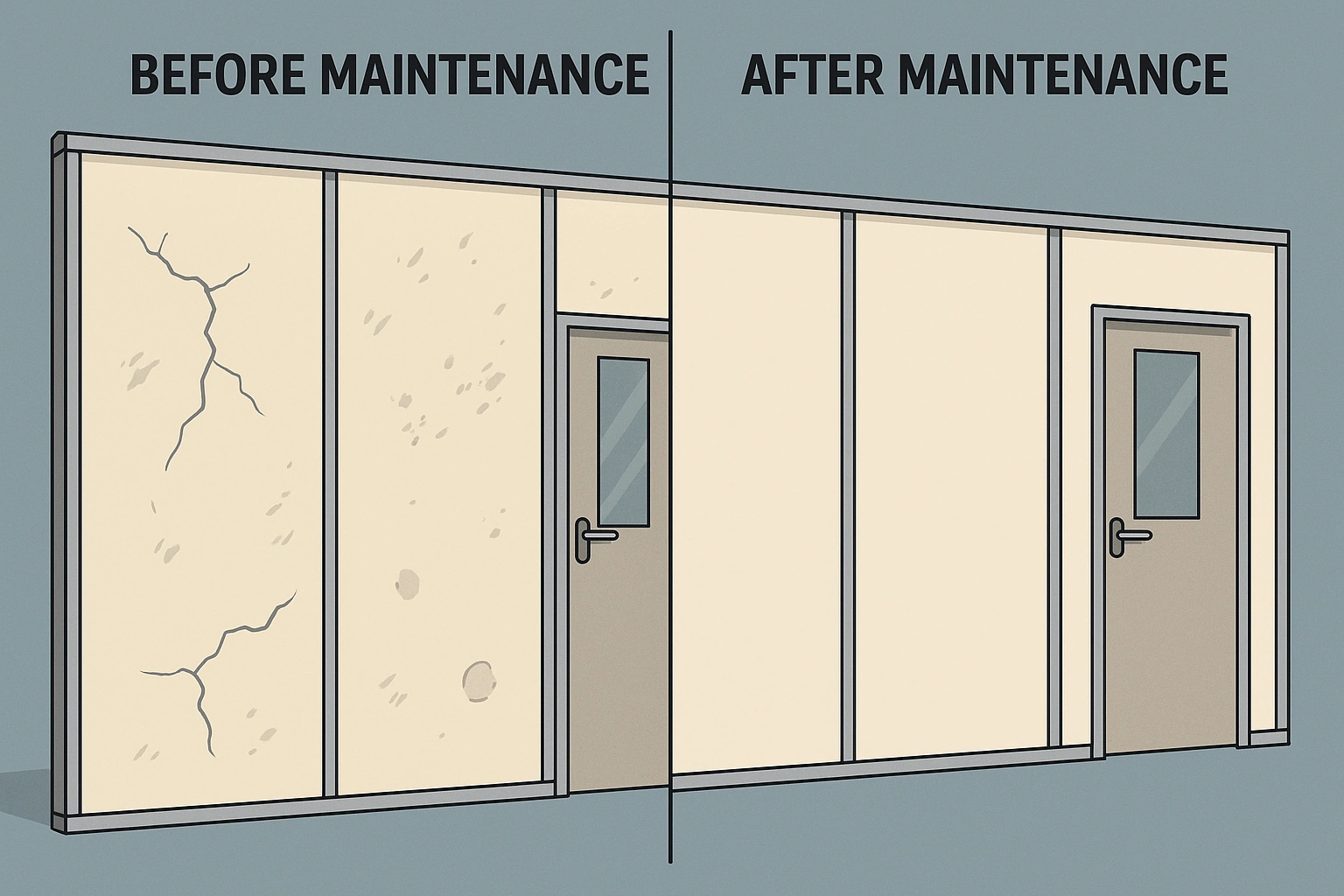

Modular temporary walls are engineered for flexibility and quick deployment, but they’re also a long-term investment. Without routine care, even high-quality systems can degrade faster than expected, leading to safety issues, costly repairs, and project delays.

Cost savings over time

Preventive maintenance reduces the likelihood of unexpected breakdowns or premature replacements. A simple inspection schedule can catch minor issues before they become major expenses.

Preventing safety and performance issues

Loose panels, damaged seals, or worn-out fasteners can compromise containment and air quality. In sensitive environments like cleanrooms or healthcare settings, these issues can lead to noncompliance or safety hazards.

Warranty and service life implications

Many manufacturers offer warranties that depend on proper care and documented maintenance. Staying on top of wall condition not only preserves coverage but also helps maximize the lifespan of your investment.

At 5DCCS, we advise our Bay Area clientsto treat modular walls like any other critical infrastructure. The better the maintenance, the longer the performance.

Materials & Components to Know

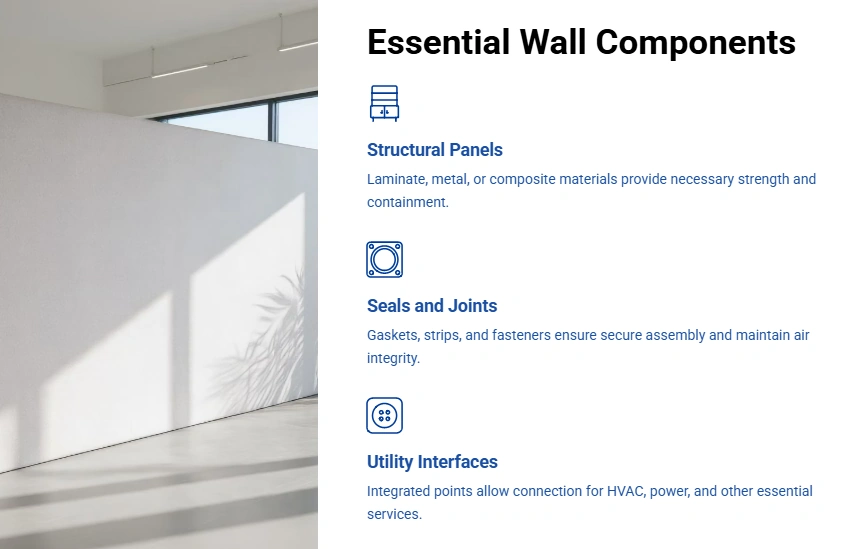

Understanding what makes up your modular wall system is the first step to maintaining it effectively. Each component plays a role in performance, durability, and ease of service. Knowing what to inspect — and how each part functions — can help you avoid issues before they start.

Panel types (laminate, metal, composite)

Most modular walls use laminate or composite panelsfor lightweight strength, while metal-faced panelsare common in cleanroom or high-durability settings. Each material has its own cleaning and maintenance needs, so always follow manufacturer recommendations.

Seals, gaskets, and joining strips

These are the unsung heroes of modular containment. Silicone gaskets, foam seals, and plastic joining stripsprevent air leakage and help maintain pressure integrity. Look for cracking, gaps, or hardening during inspections.

Frames, tracks, and fasteners

The structural elements (aluminum or steel frames, ceiling/floor tracks, and fasteners) keep the entire system aligned and stable. Loose fasteners or misaligned tracks can lead to warping or reduced containment effectiveness.

HVAC, electrical, and utility interfaces

Temporary walls often accommodate pass-throughs for ducting, wiring, or utilities. These areas need extra attention to ensure seals remain intact and no gaps are introduced over time.

By familiarizing your team with these elements, you’ll be better equipped to perform targeted maintenancethat protects system performance and extends usable life.

Routine Inspection Checklist

Consistent inspections are the foundation of effective wall system maintenance. By catching wear and damage early, you can prevent small issues from turning into major disruptions, especially in critical environments like hospitals, labs, or cleanrooms.

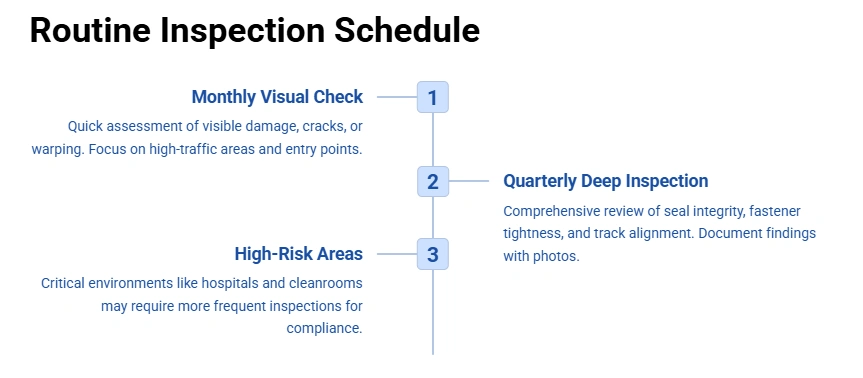

Inspection frequency (monthly, quarterly)

For most modular wall systems, a monthly visual checkand a quarterly in-depth inspectionis a reliable schedule. High-traffic or high-risk areas may require more frequent reviews.

Visible damage (cracks, warping)

Look for panel cracks, dents, surface bubbles, or warpingnear seams or entryways. Damage in these areas may impact containment performance or structural alignment.

Seal integrity and gaps

Run your hand along gaskets and seams. Check for shrinkage, detachment, or visible light leaks. Any breach in the seal can compromise air pressure and containment.

Fastener tightness and alignment

Over time, movement and vibration can loosen fasteners. Check for screws, clips, or clampsthat need tightening. Misalignment could indicate underlying stress or improper reassembly after relocation.

Track and hinge wear (if applicable)

For systems with doors, hinged access points, or sliding panels, inspect the hardware for rust, friction, or wear. Replace or lubricate as needed to maintain functionality.

Keeping a simple inspection log helps teams stay accountable and ensures nothing is missed. At 5DCCS, we recommend documenting each inspection with notes and photos when possible, especially for regulated environments.

Cleaning & Surface Care Best Practices

Proper cleaning not only keeps your modular temporary walls looking professional, it also preserves their integrity and supports compliance in controlled environments. Using the right methods and materials is critical to avoiding accidental damage.

Recommended cleaning agents and tools

Use non-abrasive cleanersand soft cloths or microfiber towels. For disinfecting, choose solutions that are compatible with your wall material, such as diluted alcohol or approved quaternary ammonium compounds. Always test cleaners in a small area before full application.

Do’s and don’ts by surface type

- Laminate panels:Use mild detergent. Avoid harsh chemicals like bleach or ammonia.

- Metal panels:Wipe with a damp cloth and dry immediately to prevent corrosion.

- Glass or acrylic inserts:Use streak-free glass cleaner and soft wipes.

Avoid using abrasive pads, strong solvents, or high-pressure spray equipment, since these can scratch surfaces or compromise seals.

Stain removal tips

Address stains promptly to prevent permanent discoloration. Use a baking soda paste or a surface-safe cleanerfor persistent marks. Do not use scrapers or sharp tools.

Glass windows or glazed panel care

Clean with non-abrasive, ammonia-free glass cleaner. For polycarbonate or acrylic inserts, choose a plastic-safe productto avoid clouding or chemical wear.

Protective coatings or sealants

Some wall systems benefit from periodic application of protective coatings, especially in areas exposed to frequent cleaning or UV light. Always refer to the manufacturer’s guidelines before applying coatings.

With regular, surface-specific care, your modular walls will continue to perform and look their bestin even the most demanding Bay Area environments.

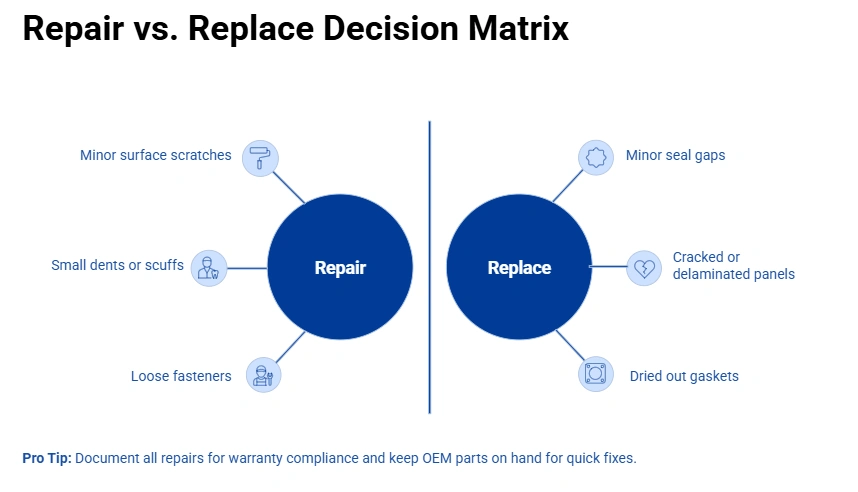

Handling Repairs & Replacements

Even with regular maintenance, modular temporary walls can experience wear, accidental damage, or unexpected system issues. Knowing when and how to repair or replace components helps minimize downtime and avoid costly disruptions.

When to repair versus replace

Minor surface damage, such as scratches or small dents, can usually be repaired. However, if a panel is cracked, delaminated, or structurally compromised, it’s best to replace it. The same applies to seals or gaskets that have dried out or lost flexibility.

Panel swap procedures

Most modular systems are designed for quick panel replacement. Panels can be removed individually without dismantling the entire wall. Be sure to follow manufacturer-approved methodsto avoid damaging adjacent components.

Field patch methods

For temporary fixes, such as sealing a small puncture, use wall-compatible patch kits or industrial tape. These should only serve as short-term solutions until a proper repair or replacement is completed.

Working with manufacturer services

If the damage is complex or involves specialized parts, contact the wall system manufacturer or your installation provider. At Construction Containment Services (5DCCS), we often assist clients with sourcing OEM parts and coordinating certified repairs.

Documenting repairs for warranties

Keep a log of all repairs, including date, location, issue, and action taken. Many warranties require documentation to remain valid, especially for long-term service contracts or regulated facilities.

Staying ahead of repairs ensures your wall system stays compliant, safe, and functional. This approach keeps your walls ready no matter how often they are reconfigured or relocated.

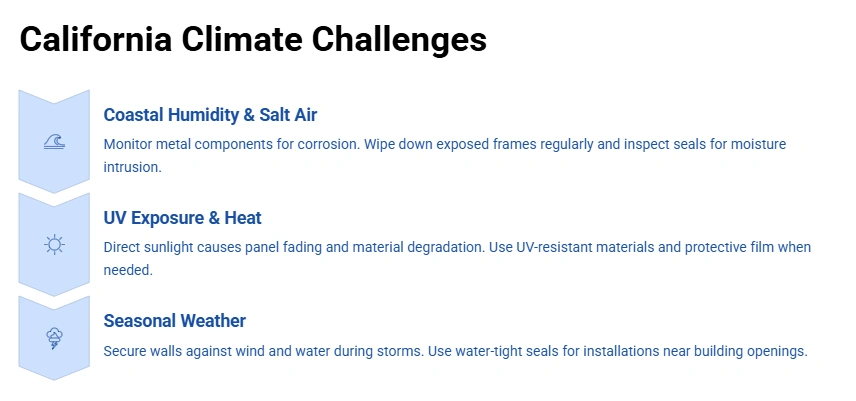

Seasonal & Climate-Related Care in California

Modular wall systems in California face unique environmental stressors depending on region and season. From coastal moisture to inland heat, understanding local conditions helps prevent premature wear and performance issues.

Effects of coastal humidity and salt air

Facilities near the Bay Area coastline should monitor for corrosion on metal components, especially frames and fasteners. Salt air can accelerate rust, so it’s important to wipe down exposed metalregularly and inspect seals for moisture intrusion.

Sun exposure and UV damage

Areas with direct sunlight, such as building perimeters or rooftop installations, may experience panel fading or material degradationover time. Choose UV-resistant materials where possible and consider installing shade or protective filmfor vulnerable sections.

Rain, wind, and storm preparedness

Although modular walls are typically used indoors, temporary installations near building openings or under incomplete roofing may be exposed to wind or water ingressduring seasonal storms. Use water-tight seals and anchor walls securely to prevent shifting or leaks.

Storage and off-season handling

When wall systems are not in use, proper storage and labelingprevents damage and confusion during reinstallation. Keep panels in a dry, temperature-controlled space, stacked vertically with protective padding between them.

Taking local weather into account during both use and storage helps extend the life of your systemand ensures reliable performance during seasonal shifts.

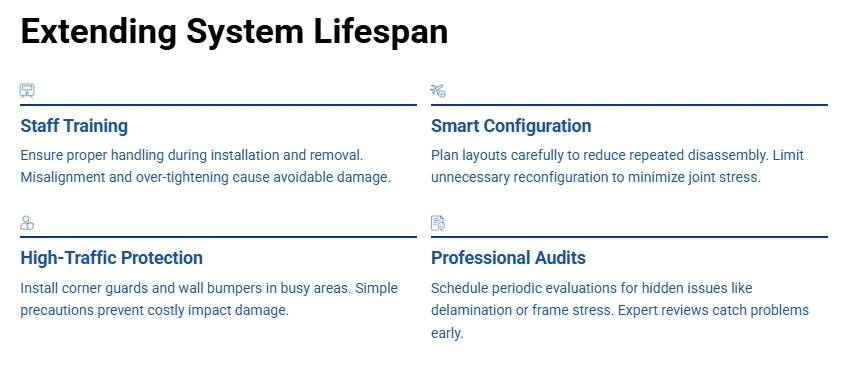

Tips to Extend Wall System Lifespan

A well-maintained modular wall system can serve your facility for many years, even with frequent reconfiguration. These best practices help protect your investment and ensure consistent performance across changing project needs.

Staff training and proper handling

Make sure that all personnel involved in wall installation, removal, or cleaning are properly trained. Misalignment, over-tightening fasteners, or dragging panels can cause avoidable wear or damage.

Limiting unnecessary reconfiguration

Modular systems are designed to be flexible, but frequent reassembly without proper handling increases the chance of wear. Plan layouts carefully to reduce repeated disassembly and minimize stress on gaskets and joints.

Protective measures in high-traffic areas

In busy corridors or active construction zones, consider installing corner guards, wall bumpers, or signageto reduce the risk of impact damage. Simple precautions can save significant repair costs over time.

Periodic professional audits

Schedule periodic evaluations with your containment provider to inspect for less visible issues such as panel delamination, frame stress, or seal degradation. At Construction Containment Services (5DCCS), we offer expert audits as part of our long-term support services.

Monitoring and hazard prevention

Keep an eye out for environmental risks such as water leaks, temperature extremes, or nearby equipment vibrations. Identifying potential hazards early helps avoid unexpected system failures.

With a proactive approach to care and handling, modular walls can remain durable, code-compliant, and visually clean throughout their entire service life.

Contact 5DCCS to discuss your temp wall maintenance or replacement needs today!