California modular temporary wall regulationsimpact how contractors, facility managers, and healthcare providers approach building safety and project compliance. From seismic anchoring to air quality standards, the rules governing temporary partitions are strict and often complex.

5D Construction Containment Services (5DCCS)helps simplify this process.

As a trusted partner in modular containment, 5DCCS works closely with clients across Californiato deliver wall systems that meet all relevant codes. Our team helps you navigate Title 24 requirements, permits, and specialized standards for healthcare and clean environments. Whether you’re enclosing a renovation zone or isolating a patient care area, we ensure your setup meets California’s building, fire, and environmental regulations.

This guide breaks down the most important rules you need to know and explains how 5DCCS supports full compliance from design to installation.

Overview of California Building Standards and Title 24

California’s building codes are among the most detailed in the nation. Title 24 of the California Code of Regulationssets the baseline for all construction, including temporary modular walls. These walls must comply with rules from several code parts, such as the California Building Code (CBC), California Fire Code (CFC), andCalifornia Energy Code.

Different project types bring different requirements. For example, healthcare facilities often need approval from the Office of Statewide Health Planning and Development (OSHPD), while schools may require plan review by the Division of the State Architect (DSA). Even for general commercial projects, temporary walls must be reviewed for structural integrity, seismic performance, and fire safety.

5DCCS ensures your modular wall systems meet these expectations.Our containment walls are engineered to align with California’s latest codes, and we stay informed of changes that could affect your project. We assist with documentation, technical specifications, and compliance checks so your team can focus on the work without delays from inspectors or regulators.

Definitions and Classification: What Is a Modular Temporary Wall?

In California’s regulatory system, how a wall is classified determines how it must comply with code. Modular temporary walls fall into a unique category that requires clear definitions to ensure correct permitting and safe installation.

A modular temporary wallis a non-permanent partition system designed for quick assembly, removal, or relocation. These systems are often used in construction, renovation, and healthcare settings to isolate work zones, protect occupants, or control air quality. They differ from permanent partitions in that they are typically not anchored to the structure in a way that would require full architectural or structural review.

However, depending on their design and use, they may still be regulated under the California Residential Code (CRC)or California Building Code (CBC). If the wall system affects fire-rated corridors, egress paths, or seismic safety, it may trigger review by local building departments.

Key classification points include:

- Demountable vs. permanent: Demountable walls are designed to be reconfigured or removed. If permanently affixed, the wall may be treated as a standard partition.

- Movable partitions: Often exempt from permit requirements, unless used in sensitive environments like hospitals or schools.

- Temporary vs. fixed installations: Timeframe, use case, and wall height may determine if a plan submission is required.

At 5DCCS, we help clients properly classify their wall systems to avoid delays or code violations. Our modular systems are pre-engineered for flexibility and compliance, and we often assist with identifying when a permit or engineering review is necessary. This is especially important in healthcare settings, where containment walls often serve both infection control and structural roles.

Permit and Plan Submission Requirements in California

In California, even temporary modular wallscan trigger permit or plan review requirements depending on how they’re used. These rules are enforced by local building departments, with additional oversight from agencies like DSA(Division of the State Architect) and OSHPD(Office of Statewide Health Planning and Development) for schools and healthcare facilities.

When Is a Permit Required?

A permit may be required if the modular wall:

- Obstructs means of egressor corridors

- Interfaces with fire-rated walls or ceilings

- Is located in a regulated environmentlike a hospital, lab, or school

- Involves anchoring, bracing, or seismic reinforcement

- Exceeds temporary thresholds for height, duration, or material type

Each jurisdiction may apply these rules differently, so it’s essential to consult with the general contractor (GC)or property manager, who is typically responsible for securing all necessary permits for the project.

What Is Typically Submitted?

If a submittal is required, it may include:

- Project layout and wall placement drawings

- Product data and specifications

- Structural or seismic documentation (when applicable)

- Fire rating and material complianceinformation

- VOC or CARB certifications (for indoor air quality)

5DCCS’s Role in Supporting Compliance

While 5DCCS does not handle permitting, we work closely with project teams to ensure the documentation and materialswe provide support a smooth approval process. Our modular wall systems come with detailed spec sheets, code compliance data, and technical drawings that can be submitted by the GC or project lead as part of a permit package.

We help simplify the review process by supplying everything your permitting authority will likely requestregarding the containment wall system. Our experience across California jurisdictions allows us to anticipate what’s needed and proactively support your team’s compliance efforts.

Structural and Seismic Requirements for Modular Walls

In California, seismic safety is not optional. All building components, including temporary modular walls, must meet performance expectations in the event of an earthquake or related movement. Even when used for short-term containment, these systems are expected to remain stable, safe, and code-compliant.

Structural Expectations

Modular wall systems should be able to resist:

- Lateral forcesfrom seismic events or high foot traffic

- Vibration or impactfrom nearby construction equipment

- Wind loads, especially in open-air or exposed environments

Depending on the location and facility type, walls may require anchoring to ceilings or floorsand the use of bracing systemsto maintain structural stability. In hospitals, schools, and state-regulated facilities, these expectations are even more stringent.

Seismic Zones in California

Most of California falls under Seismic Design Categories D or E, which are among the highest risk classifications in the U.S. This means even temporary systems must perform predictably during seismic activity.

Regulatory bodies like the Division of the State Architect (DSA)provide specific criteria through interpretations such as IR PC-2, which guides how prefabricated and modular systems must respond to structural and seismic demands.

How 5DCCS Ensures Safe, Compliant Installations

5DCCS supplies modular containment systems engineered to meet California’s structural and seismic expectations.Our wall solutions include optional anchoring kits, impact-resistant panels, and design elements that enhance lateral stability.

We also provide clients with structural data and support materials that can be used during plan review or shared with engineers and inspectors. Whether you’re building in a healthcare setting, an educational campus, or a commercial zone, 5DCCS ensures your temporary wall system won’t become a compliance liability.

Fire and Egress Rules for Temporary Partitions

Fire safety is a top priority in California’s building codes. Whether permanent or temporary, any wall system must support life safety by preventing fire spread and preserving safe exit routes. Modular temporary wallsare no exception, especially when installed in healthcare facilities, schools, or commercial buildings with high occupancy.

Fire Rating and Material Requirements

Depending on the project type and wall location, modular systems may need to:

- Use materials with a Class A fire rating

- Avoid altering rated corridors or smoke barriers

- Maintain minimum clearances around exits and fire equipment

- Comply with NFPA 101 (Life Safety Code)and the California Fire Code (CFC)

These requirements are especially strict in hospitals, labs, and state-owned buildings. Fire marshals or safety officers may require documentation to verify that modular systems meet fire spread and smoke control standards.

Egress Considerations

Clear paths of egress are critical in any building. Temporary partitions cannot:

- Reduce corridor widths below code minimums

- Block access to emergency exits, alarms, or extinguishers

- Obstruct exit signage or emergency lighting

A misaligned wall layout could result in safety violations or inspection delays. This is why early planning and code coordination are so important.

How 5DCCS Supports Fire Code Compliance

5DCCS supplies modular wall systems built with fire safety in mind.Our materials meet industry-standard flame spread ratings and can be configured to respect egress pathways and fire access zones. We assist clients with layout planning and provide all required documentation for code review or inspection.

Our goal is to ensure your containment system supports life safety, not hinders it. When fire code compliance is on the line, we help you stay ahead of the requirements.

Environmental and Indoor Air Quality Rules

California enforces some of the nation’s most rigorous environmental regulations, especially when it comes to materials used indoors. For modular temporary walls, this means meeting strict standards for chemical emissions, VOC limits, and material safety certifications. These rules are critical in hospitals, schools, and other spaces where occupant health is a top priority.

Key Regulations to Know

Modular wall systems installed in California must comply with:

- CARB Phase 2(California Air Resources Board) limits for formaldehyde emissions in composite wood products

- Low-VOC (volatile organic compound)thresholds for coatings, adhesives, and sealants

- Material labeling and documentationunder the California Green Building Standards Code (CALGreen)

- Indoor air quality benchmarks that may be required by local jurisdictions or healthcare authorities

Failure to meet these standards can result in rejected installations, health complaints, or delays in occupancy.

5DCCS’s Approach to Material Safety

At 5DCCS, we prioritize environmental compliance across all modular containment systems. Our wall materials are selected to meet or exceed CARBand low-VOC requirements, making them suitable for use in sensitive environments like hospitals and labs.

We provide clients with detailed certification documents, emission test results, and manufacturer safety data sheets to support regulatory review and material tracking. These documents are essential for projects seeking LEED points, OSHPD approval, or CALGreen compliance.

Why It Matters

Choosing compliant materials is not just about passing inspections. It’s about protecting the health of workers, patients, and building occupants. With 5DCCS, you can be confident that your containment walls contribute to a safer, healthier indoor environment while meeting California’s environmental standards.

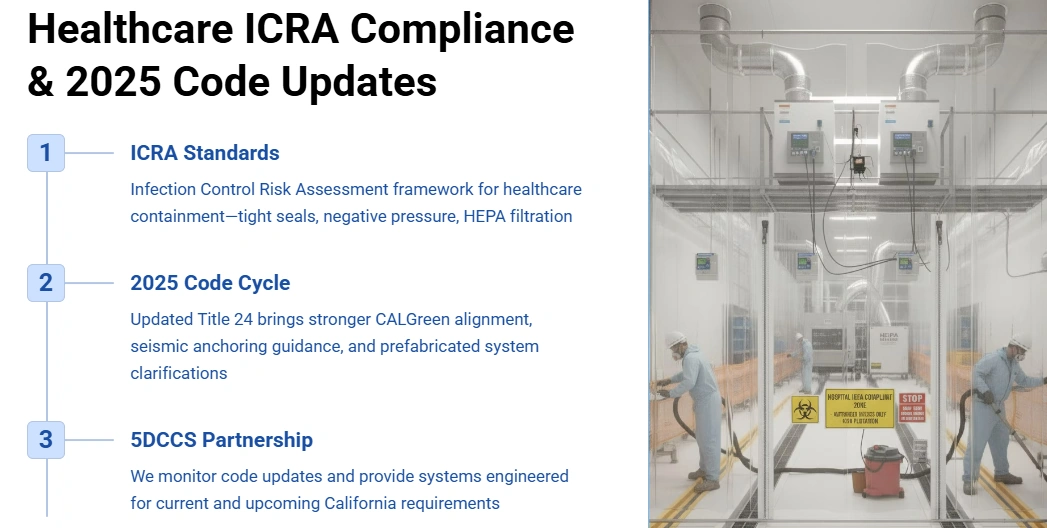

ICRA, Healthcare, and Clean Environment Containment Standards

In hospitals and healthcare facilities, containment systems are held to a much higher standard than in general construction. These environments demand strict control over dust, airflow, and contamination risks. California follows the Infection Control Risk Assessment (ICRA)model to classify containment requirements and ensure patient safety during construction or renovation.

What Is ICRA?

ICRAis a framework used by hospitals to assess the risk of infection during construction activities. It outlines what type of barrier system is needed based on several factors, including:

- The type and duration of the construction work

- How close the work is to patient care areas

- The risk level of the patient population

- Whether the project affects sterile or surgical zones

ICRA classes range from basic dust barriers to full enclosures with sealed access, negative pressure, and HEPA filtration.

Containment Expectations in Healthcare

To meet ICRA requirements, modular wall systems must:

- Form a tight seal against ceilings, floors, and walls

- Support negative air pressure to prevent airborne contaminants from escaping

- Integrate with HEPA filters and environmental monitors

- Be constructed from smooth, non-porous materials that are easy to clean

- Install and remove without introducing dust or debris into occupied areas

These standards are reviewed by infection control staff and often audited by OSHPD or third-party inspectors.

How 5DCCS Helps Healthcare Teams Stay Compliant

5DCCS offers modular wall systems engineered for healthcare settings and ICRA compliance.Our containment solutions are compatible with Class III and IV ICRA requirements and can be customized to work with negative air machines, sealed doors, and continuous monitoring.

We support infection control teams, facility managers, and general contractors by supplying cleanable, airtight wall systems along with the documentation needed for internal approval. Our systems are trusted across California hospitals because they reduce risk while keeping patient care uninterrupted.

Recent and Upcoming Code Changes in 2025

California’s building codes evolve on a regular cycle, and the 2025 updates to Title 24bring important changes that affect modular temporary wall systems. Contractors, facility managers, and containment providers must stay informed to ensure continued compliance as the new codes take effect.

Overview of the 2025 Code Cycle

The California Building Standards Commissionupdates Title 24 every three years. The 2025 cycle includes changes that impact:

- Energy performance and material efficiency

- Indoor environmental quality

- Seismic and structural resilience

- Healthcare and school facility regulations

While many updates focus on permanent construction, some provisions affect temporary systems, especially those used in regulated environments or near fire-rated assemblies.

Impact on Modular and Prefabricated Systems

Key trends in the 2025 updates include:

- Increased attention on off-site construction and prefabricated systems

- Stronger alignment with CALGreenand low-VOC material requirements

- Clarification on when plan review is requiredfor temporary partitions

- Updates to seismic anchoring guidance, especially in public projects

These changes may affect product selection, installation methods, and how temporary systems are reviewed during permitting.

How 5DCCS Stays Ahead of the Curve

5DCCS actively monitors code updates and adapts our systems to meet the latest standards.We review updates from the Building Standards Commission, DSA, and OSHPD to understand how the changes will impact containment projects.

Our goal is to help clients avoid surprises during inspections or plan reviews. Whether your project starts before or after the 2025 code cycle takes effect, 5DCCS can guide you in selecting a modular wall system that meets both current and upcoming requirements.

Best Practices for Compliance and Risk Mitigation

Staying compliant with California regulations is not just about knowing the codes. It also requires strong planning, clear communication, and the right containment tools. Mistakes in classification, documentation, or layout can lead to costly delays, failed inspections, or even safety hazards.

Here are proven strategies to keep your modular wall installations fully compliant.

Engage Early with Project Stakeholders

Start coordination early with:

- General contractors

- Facility engineers

- Infection control teams (for healthcare settings)

- Building department representatives

Early discussions help define the containment scope, identify regulatory touchpoints, and determine whether plan submittals will be required.

Use Systems Designed for California Codes

Not all modular wall systems are created equal. To ensure compliance, choose systems that:

- Have known performance in seismic zones

- Offer fire-rated and low-VOCmaterial options

- Can be securely anchored or sealed when needed

- Are supported with technical data, safety documentation, and installation guidance

5DCCS provides modular containment walls built specifically with California’s regulatory environment in mind.

Maintain Documentation and Track Changes

Always retain:

- Product data sheets

- Layout drawings

- Environmental compliance reports

- Fire and seismic documentation

- ICRA classification forms (for healthcare projects)

If field conditions change, update your plans and confirm that the containment setup still meets applicable codes.

Partner with an Experienced Provider

Compliance is easier when your containment partner understands the regulations. 5DCCS brings deep experience in modular wall systems, installation strategy, and support documentation.We collaborate with your team to reduce regulatory risk while keeping your project timeline intact.

Ready to get started?Request a consultationto discuss your space needs today.